Your crankcase is first bathed in hot caustic to clean off all foreign matter. It is then steam cleaned to power out all tiny holes and crevices. Also, any counter weights, temporary repairs or plugs are removed. The crankshaft is now magnetized, then sprayed with a solvent containing fine iron particles. These show fluorescent light to inspect each bearing surface, key way, webbing and radius.

Additional inspections from magnetic particle to ultrasonic are performed periodically as needed throughout the process. A complete written report is prepared and attached to your crankshaft. This compares the shaft with original O.E.M. standards and the report accompanies your crankshaft during restoration. The report is checked at every stage by each job supervisor and is triple-checked by quality assurance inspectors all the way through to completion of salvage and restoration.

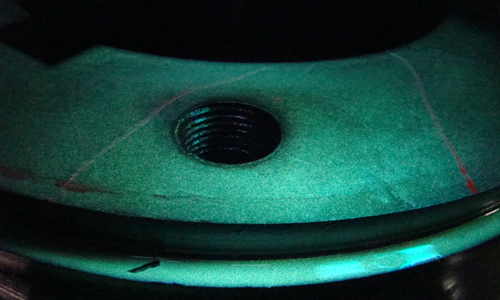

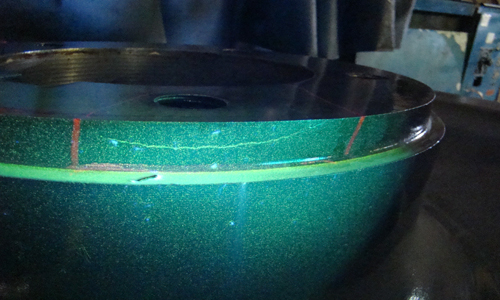

After inspection is completed, the crankshaft is ready for pre-grinding for chrome with care taken to their radius of the crankshaft as so not to remove any strength from the parent material. The undersize of the crankshaft before chrome plating depends on application of crankshaft and service that the crankshaft will be in.